Welcome to the

Run on Sun Monthly Newsletter

In this Issue: |

July, 2015

Volume: 7 Issue: 1

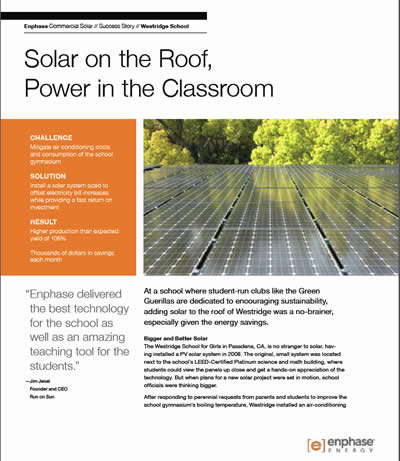

Enphase Revisits Westridge Solar ProjectA little over three years ago (my how time flies), we installed a 52kW solar project at the Westridge School for Girls, here in Pasadena. At the time, the project got a fair amount of attention (including an award from the City), was featured in a video (watch it here), and was the lead story in Enphase Energy's Summer 2012 Newsletter. Three years down the road, the folks at Enphase decided to circle back and check-in to see how the Westridge project had performed over the years - both in terms of saving money for the school, as well as being incorporated into the curriculum (another key goal of the project).

We are very proud of our partnership with Westridge and we look forward to doing another project with them in the near future. Likewise, we are grateful for partners like Enphase Energy who are as committed to producing long term solutions as we are. That is one powerful pairing! |

“We are very proud of our partnership with Westridge and we look forward to doing another project with them in the near future…”

Commercial Solar:

Step-by-Step

from

Run on Sun

Founder & CEO

Jim Jenal

Now available on Amazon.com

in both

Print & Kindle versions.

Step-by-Step

from Run on Sun

Founder & CEO

Jim Jenal

Now available on Amazon.com

in both Print & Kindle versions.

Will LA County Clean up its Act?We couldn't suppress an ironic smile when we read the headline, Los Angeles [County] Assembling Solar Action Committee to Address PV Challenges. "Physician, heal thy self," immediately popped into mind given the propensity of LA County to create those very challenges! Here's our take on what LA County is up to. According to the article at Solar Industry magazine's website:

Oh heavens, don't get me started! Well, ok, too late. How about this for just one example (from many): we recently completed a commercial project in LA County. When we submitted our single line drawing to DPW (prepared and stamped by a licensed electrical engineer), it came back with nine "corrections". Ultimately we were able to demonstrate to DPW that seven of the nine did not even relate to our project since they all were focused on either the DC side of a PV system (and our Enphase-based system had no such components) or they related to the size of a non-existent load-side breaker. It took three iterations to whittle those bogus objections away, until we got down to the final nut: bonding. Now one of the two remaining concerns was legit - DPW wanted our plans to call out two grounding rods. Fine, easy, done. But the remaining sticking point was a killer. We were using Everest Solar racking, which has UL 2703 listed splices for its rails that bond those splices together.

DPW refused to accept the splices for bonding, requiring bonding jumpers (like you see in the picture) across each splice. Which begs the question: what is the point of manufacturers building products to meet a national spec, if a local jurisdiction like DPW can simply say, "not in my backyard?" Everest also had at the time an approved mid-clamp with WEEB solution for bonding between modules. In Pasadena, just across the street, that combination would have been approved without comment. But not DPW, which rejected the WEEB solution, requiring us to run a continuous #6 wire from module to module - all 246 of them! Now when you talk to the folks at DPW they insist that this is all about safety. To which we respond - rubbish! What is the failure scenario that we are actually protecting against? In theory, you are trying to ensure that no metallic part becomes energized without a pathway to ground. That way if there is a fault, and someone touches the affected metal surface, current will not flow through them to ground (causing injury) because it has a lower resistance path to ground via the system bonding. That is certainly a noble goal, but did the changes DPW insisted upon improve safety in the real world? This array is on a free standing structure, 14' above the ground so it isn't likely that someone would ever casually come in contact with a metal surface to begin with. But even if they did, what would that failure mode have to be? On the one panel that happens to develop a fault, a minimum of two, and in most cases four, WEEB clips would have to fail at the same time! Call me cynical, but I find that a highly unlikely event. In contrast, the economic consequence of what had to be done to placate DPW was very real, adding thousands of dollars in parts and labor to the cost of the project, for an at best marginal improvement in safety. So we are all for DPW taking steps to eliminate "PV challenges", but we would suggest they look at cleaning up their own act as the proper place to start. |