Welcome to the

Run on Sun Monthly Newsletter

In this Issue: |

March, 2013

Volume: 4 Issue: 3

Lancaster Lights Up for Solar!

While the mandate is unusual, having solar-powered homes in the desert certainly is not. In fact, KB Homes just announced completion of their 1,000th solar home in California, of which more than 200 are located in Lancaster. Part of what is driving attention to the Lancaster solar mandate is that it was spearheaded by the City's Republican Mayor, R. Rex Parris. Mayor Parris indeed appears to be a colorful fellow - he recently signed on to be Plaintiff's counsel in a voting rights lawsuit against the neighboring city of Palmdale - but we have never understood the alleged partisan divide over solar. After all, what could possibly be more conservative than reducing the burning of fossil fuels and taking advantage of a free source of power? In any event, the draft ordinance notes that part of its purpose is to "encourage investment in solar energy on all parcels in the city," and who could fault that as a goal? To which we say to our northern neighbors - we like the high desert and would be more than happy to help the commercial buildings in Lancaster to go solar! Just give us a call - we're not that far away! |

“What could possibly be more conservative than taking advantage of a free source of power?”

Help Spread the News!

Solar Trends: Storage & Lower CostPredicting the future is always fraught with hazards but a recent survey caught our eye with a bold prediction: nearly one-third of solar installers/integrators world wide expect to utilize storage in more than 40% of their installs by 2015! Oh and they need microinverters to come down in cost by 50% before they are willing to adopt them!!! Numbers like that beg for some analysis, so stay with us. Booming Market for StorageThe survey in question was conducted by IMS Research (h/t to SolarIndustryMag.com) and included global installers, integrators and wholesalers. Among respondents from the U.K., Germany and Italy, the addition of storage capability was cited as the most important requirement for inverters over the next two years. We aren't surprised by this result. As the penetration of PV systems onto local grids increases, grid operators and utilities start to complain about solar undermining grid reliability. (Well, OK, utilities are actually complaining about losing market share, but that is not the concern of the ISO.) Likewise for many commercial solar clients, PV alone may not be a complete solution if the client's electric bills fall under a demand-charge rate structure and their peak demand falls outside of the peak output for their PV array. (Add Feed-in Tariff clients with time-of-delivery factors and you have yet another potential market for cheap storage.) According to the survey, respondents were looking to add storage for 10-30% additional cost, but is that a realistic expectation? Not from any of the products we've seen so far. (The survey noted that 30% of respondents were willing to pay even more - which from what we can tell, they will certainly need to do!) Ultimately, local storage for distributed generation will boom if the economics justify it - whether because net metering becomes less desirable (or even unavailable), or if demand shifting or time-of-delivery factors boost the ROI enough to overcome initial costs. How Low Can You Go?

How does such reluctance make sense? Let's look at a typical 5kW residential project using either Enphase microinverters or SMA string inverters. Assume that we are using twenty 250 Watt modules to power both inverter types. So we would need 20 microinverters and one string inverter. Enphase cost - around $3,500 for microinverters plus cable. String inverter cost - about $2,800. Labor? Well someone has to hang that SMA 5000 on a wall downstairs (preferably somewhere in the shade!) while someone else is mounting microinverters to the rails on the roof. Pretty much a push. (We actually have lower labor rates for microinverters than we do string inverters, but that's just us.) Which makes the microinverter about 25% more expensive going in. So for the installer it might look like they have a better deal with the string inverter, but what about the client? Our testing shows a 15% improvement in yield and that goes even higher depending on the amount of shading at the site. Beyond that, the microinverter comes with a 25-year warranty, the string inverter only 10. Which means for the client, they are going to have to spend an additional $2,800 or so ten years down the road when their string inverter dies (sooner if it is baking in the sun). All of which argues quite convincingly that the microinverter is the better deal for the installer's client - which last time we checked was supposed to be the point of the exercise. We are all for price reductions, but we suspect that folks who say microinverter prices must fall 50% before they will consider using them have already decided that they will never use them. Of course, installers are entitled to run their business as they see fit, but it certainly isn't a lack of value to the client that is keeping these installers from taking the plunge with micros. |

How Things Fail:

|

|

Conduits came up from the ground into a neatly mounted gutter to feed each of the eight inverters. This was a well thought-out piece of work - and everything appeared to be operating properly. |

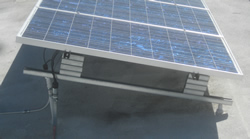

There were two more sub-arrays on the roof of the building, and there too, everything appeared to be in order:

We were only there to take measurements and assess the performance of the system - and everything seemed fine.

But then this bit of "engineering" caught my eye:

Nevertheless, I decided to go around to each row and make sure that everything was still secure.

That's when things really went south. Nearly a third of the rows had one or more corners that were no longer secured to the unistrut - in some cases both north and south edges were free, meaning that the only thing holding that module to the "rails" were a pair of mid-clamps that could not prevent sideways motion! Given what we had seen a Pasadena windstorm do to an array that was far better secured, it was very disturbing to imagine the future of this brand new array.

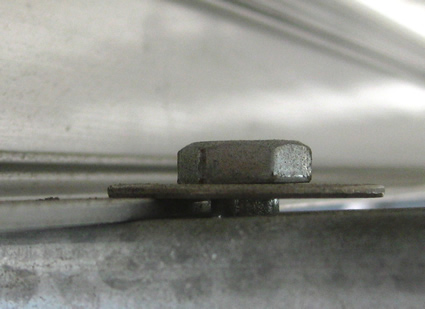

Upon closer inspection we figured out how the geniuses who had built this system intended it to work. Check this out:

At the bottom of the photograph is the piece of unistrut serving as a rail. On the left we see the lip of the solar module and holding it against the rail is a bolt that is screwed into a channel nut in the unistrut. But that bolt doesn't pass through the module frame (even though the manufacturer has provided pre-drilled holes precisely for that purpose). Instead, the only thing keeping this in place is the friction between the module lip and a fender washer which is only supported on the left side. This is laziness/ignorance of staggering, dangerous proportions. How hard would it have been to adjust the unistrut to align with the pre-drilled holes? But the wizards who built this either didn't realize that would be a good thing to do, or they simply couldn't be bothered to do it!

The ultimate results of this shoddy work were everywhere to be seen. Here are several images of the all-too predictable failures:

Here the bolt and washer is far to the left of the module lip that it is supposed to be securing to the unistrut. Did the wind over the past year move it that far away? Or was it never even put in its "proper" place by the install team? Either way, there is nothing holding this module to the unistrut on this end.

Keep in mind - as you can see from our first picture of the roof array - these modules are exposed to the full force of the wind coming out of the north. All of these failures to properly secure these modules have developed in less than a year of service. What will happen when the next big windstorm sweeps into town?

Pity the company that owns this system. They paid top-dollar to a supposedly reputable company to design and install this system and now they have a crisis on their hands through no fault of their own. Indeed, once down on the ground we took a closer look at the carport structures and it appeared that the same "technique" had been used to secure the panels to the steel members of the carports! Which meant that all of the edge-mounted modules were in danger of coming off the structure.

So what lesson can we learn from this? Some failures occur because of mistakes or even bad luck - but such was not the case here. The crew that built this system either utterly failed to comprehend the nature of their task, or they simply didn't give a damn. (And again, this site was inspected so what was the inspector thinking when looking at this system?)

The company that paid for this installation is a very professional organization and they obviously believed that they were hiring an equally professional installer - but they certainly didn't get what they paid for. How might they have protected themselves? One possible hedge would have been to hire a consultant - possibly a NABCEP certified installer or a professional engineer - to look over the installation before making final payment. That at least would have given them some notice of problems before modules started flying off the roof. Indeed, in perhaps the greatest irony of this entire episode is that the system was actually performing extremely well. The reason that we had been called out to the site in the first place was not an issue at all.

But all too often, when things fail, they do so in ways that we never imagined.

By the way, in Part 1 of this series we looked at a residential solar system that had stopped working - largely because it was left to bake in the sun until finally a key component failed, dramatically.