Categories: "Utilities"

05/04/12

Categories: All About Solar Power, PWP Rebates, PWP, Commercial Solar, Non-profit solar, Westridge PAC Project

Westridge Project Grabs Pasadena Weekly's Green Issue Front Page!

Readers of this blog will know all about the 52.3kW solar project that Run on Sun just recently completed installing at Pasadena’s renowned Westridge School for Girls. Now that project has become the cover story in the Annual “Green Issue” of Pasadena Weekly.

Readers of this blog will know all about the 52.3kW solar project that Run on Sun just recently completed installing at Pasadena’s renowned Westridge School for Girls. Now that project has become the cover story in the Annual “Green Issue” of Pasadena Weekly.

Titled, “Solar Flair: New solar installation at Westridge School brings environmental lessons to life,” the piece features interviews with Westridge’s Head of School, Elizabeth McGregor, Facilities Manager Brian Williams, and three students who are part of the school’s environmental group known as the Green Guerrillas. The story reveals the school’s deep commitment to sustainability in everything from solar power to drought tolerant plants.

This first of what we hope will be many solar projects at Westridge really highlights the value of these projects for all schools, especially those in the Pasadena Water and Power service territory. Good rebates and a solar company that really understands your goals makes a solar power system installed by Run on Sun a “no-brainer.”

Contact us today and let’s get going with YOUR solar project!

Categories: PWP Rebates, PWP, Commercial Solar, Non-profit solar, Westridge PAC Project

The Permit Process - Installing Solar at Westridge - Part 2

In Part 1 of this series about Installing Solar at Westridge School, we looked at the process of putting our materials together for the rebate application. With the rebate safely reserved, it was time to turn to pulling the permits for the job. A solar project of this size involves two separate permits - building and electrical - but four points of inspection - fire, electrical, building, and utility. We had already provided the utility, PWP, with the materials they needed but now we needed to load up for the permit center.

Assembling the Necessary Materials

The permit process addresses an entirely different need than does the rebate application. The permit process is intended to guarantee that the proposed system, as designed, satifsfies all applicable codes and standards. In theory, once you have successfully pulled the permit, the inspection process should simply be a matter of showing the inspector that you built the system as it was approved when you pulled the permit.

This project presented one signficant challenge - the actual attachment of the system supports to the roof. While the roof looked conventional enough, that was not a wooden truss underneath those shingles. To the contrary, our roof was built from a 20 gauge “Type B” steel deck with two layers of 5/8″ plywood, followed by 3″ of solid foam insulation, followed by 3/4″ of plywood to which the roofing materials themselves - membrane, felt and shingles - were attached. So the question arose: what would be a sufficient way to attach our standoffs to this roof to provide the requisite resistance to wind loads - the effect of which had recently been demonstrated in Pasadena in such a disastrous fashion?

To help answer that question we turned to the structural engineer (SE) who had originally done the load calcuations for our building. Could we use a “FastFoot” and simply put multiple screws into the wooden decking materials? Surely with enough screws - the FastFoot will allow for up to eight - we could reach the required pull-out resistance. Unfortunately, that wouldn’t work since the engineer could not guarantee the manner by which the plywood materials were secured to the underlying steel deck. In other words, while we could be sure that our array would remain attached to the plywood, we couldn’t be sure that the plywood would remain attached to the building! Images of Wizard of Oz roofs flying through the air filled my mind - clearly we would need another way!

The engineer suggested that we could use carriage bolts that ran all the way through the steel roof and were bolted together on the back side. Certainly such an approach would guarantee that our array and the roofing materials stayed connected, and indeed, you would have to separate the steel deck from the steel framework of the building for that method to fail. Unfortunately, that wouldn’t work either since there was no way to access the back side of the roof in order to complete the connection.

“Nine-Inch Nails” Meet 8-Inch Screws!

There was one other approach - a company by the name of Triangle Fasteners sells some very strong, very long, self-tapping screws (called “Concealor screws“) that could drill their way into the steel deck and provide us with the required pull-out resistance. The bad news - our distributors only sold screws up to 7″ long - and that would not be long enough to guarantee that our screws made it through the decking. A call to the manufacturer revealed that in fact, they did make 8″ screws, they even made 9″ screws! Excellent! We now had a solution that our SE could bless. It was time to go pull our permits.

Fear and Loathing at the Permit Center

Anyone who has ever pulled a permit knows the combination of emotions that you encounter upon entering the building: fear that something you haven’t considered will suddenly become A Really Big Deal, loathing for the interminable waiting, and of course, the pain of paying for it all. Dentists’ waiting rooms tend to be cheerier places.

Pasadena’s permit center is certainly better than most: it is a comfortable old building across the street from the beautiful City Hall. They have a clever scheduling system that routes you among the different windows: Building and Safety, Zoning, Historical Preservation (very big in Pasadena but not a factor for solar projects), Fire, Permit Processing and, last but certainly not least, the Cashier. A solar project applicant must navigate their paperwork through every one of those windows before exiting with your Grail - a stamped set of plans and a bright Yellow permit folder where inspection sign-offs will be recorded.

First stop - Building and Safety.

Building and Safety

The building and safety folks are responsible for reviewing your plans for conformity with state and local codes and standards - a really important task. First, however, you have to speak with someone who knows what you are showing them and on our first trip to the permit center, no such person could be found! The gentleman behind the B&S desk was very polite, and you could tell that it pained him to inform us that after our thirty minute wait, he couldn’t help us. Moreover, none of the people who “understood solar” were available - we would have to come back tomorrow.

Tomorrow dawned cloudy but we were determined to press forward. This time our 35 minute wait was rewarded with an appearance before someone who was prepared to pass judgment on our plans! We walked him through each of our sixteen 24″ x 36″ pages, explaining as we went exactly what we were doing and where the answers to his questions could be found.

All seemed fine, but then he started throwing us some curves.

Our SE had done his calculations for a basic wind speed of 85 mph - the same wind speed we had always used for load calculations in Pasadena.

“No,” said the man behind the desk, “You have to use 100 mph.”

“Really? Since when?”

“Since the windstorm in Pasadena at the end of November,” we were told. (Never mind that the wind speed never reached 85 mph in Pasadena, let along 100 mph, during that terrible event.)

“Really? Where was that published?”

“It wasn’t,” he conceded, but simply told us that we needed to revise our calculations for 100 mph or he wouldn’t approve them. That meant another iteration with our SE and another trip back to the permit center.

Now the good news here is that we were certain that our system would easily handle 100 mph winds (or 120 mph, for that matter) so this change in policy did not pose a danger to the project going forward. But changing the basic wind speed for an area from 85 to 100 mph is something of a big deal and will add to the expense of many projects that need permitting. Shouldn’t there be a more public process before such a change is implemented?

The other curve sent our way was really just odd.

We did a detailed drawing showing our attachment method as it penetrated the various layers of roofing materials and made contact with the steel deck beneath. We drew that straight up on the page and included multiple elevations in our sixteen pages that showed the pitch of the roof and indicated that the array was installed on top of our attachment method, parallel to the roof.

“Not good enough,” we were told.

“Why? What’s missing?”

“You need to show the attachment at the slope of the roof.”

“Really? We show you the slope of the roof, we gave you the detail of how the attachment connects to the roof and we told you that the array is parallel to the roof. How is that not sufficient?”

“You need to add a drawing that shows the array attachment and which reflects the slope of the roof.”

“Really? So what you want is for me to rotate the image of our attachment 13° to reflect how it will be pitched on the roof?”

“Yes.”

Sigh. Ok, back to the drawing board (or more accurately, the computer screen).

Fortunately, our SE was able to redo his calculations in short order. And not surprisingly, it was also pretty easy to take our attachment image and rotate it. We printed up the revised plans and headed back to the permit center.

Surprise - there was yet another person behind the counter this time. Whereas his predecessor seemed to be actively looking for little things to complain about, this fellow could not have been more helpful. He looked at our revised load calculations - veryifying that they had been done for 100 mph and that the SE had concluded that all was well - and then proceeded to stamp our plans. (I had pointed out our added, rotated drawing, but it was clear that he wasn’t interested in that at all.) After he stamped our plans, he then took them himself to the zoning and historical preservation desks and secured those sign-offs as well! Wow! He saved us an hour of waiting in those queues and he seemed genuinely helpful and concerned. What a pleasant contrast! We were well on our way with just one real substantive hurdle remaining - the Fire department.

Fire

The California State Fire Marshall developed a set of guidelines that provide guidance as to how fire departments should permit and inspect solar installations. The guidelines call for space to be set aside for pathways around the array and for venting of smoke in case of a fire. The guidelines call for different restrictions based on the size and shape of the roof and whether it is a residential or commercial building.

(While the document from the Fire Marshall is labeled “guidelines", most localities seem to treat it as gospel. Even more curious, the guidelines clearly say that they are just that, guidelines that do not have the force of law until a local jurisdiction passes an ordinance adopting the guidelines as regulations. We have yet to see such an ordinance.)

Our building plan included a three-foot set aside around both sides of the array and from the ridge, and was augmented by automatic smoke ventillation devices already built into the roof. But that was not sufficient - the fire official wanted us to provide a four-foot clearance on all three sides. Yet another trip to the computer.

We returned with our revised drawing, showing four feet of clearance as requested. But now there was another concern - the same fire official now wanted us to open a walkway in the middle of the array. (We already had access paths for potential maintenance, but they were not wide enough to be considered a walkway.) No matter that our roof was not at all like the flat roof with parapet shown in the guidelines, we still needed to provide a walkway. There was only one way to do that - take out a column of panels. Together we X-ed out seven panels and thereby created a walkway. The fire official was now satisfied - she signed off on our plans.

Done

And just like that, we were done. Well, not quite - there was still the little matter of paying for all this. Here we made out surprisingly well. Unlike some cities that gouge solar applicants (and you know who you are!), Pasadena’s fees were quite reasonable. Total cost for our now 52.25kW solar project? $732. Sadly, we know of residential projects one tenth that size in other cities where the permit fees have exceeded $1,000! (But that’s a story for another day.)

Altogether, it took us four separate trips to the permit center, three plan revisions, and a little over $900 in expenses to secure our permit.

Now all we needed to do was get the materials to the job site on time, and complete the installation in the two week window that we had to mesh with the School’s schedule. The real work was about to begin…

Categories: PWP Rebates, PWP, Commercial Solar, Non-profit solar, Westridge PAC Project

Installing Solar at Westridge - Part 1

In November of 2011, Run on Sun was hired by Westridge School for Girls to install a 54 kW solar system on the roof of the school’s Fran Norris Scoble Performing Arts Center (the “PAC” as it is known on campus), and that project was just recently completed. This multi-part series will document the process by which we went from a signed contract to a signed-off solar power system. Not surprisingly, there were a few twists and turns along the way that had to be resolved before we could deliver a successful project, and this series will showcase those developments in the following five parts:

Part 1 - The Rebate Application (this post)

Part 2 - The Permit Process

Part 3 - On the Ground

Part 4 - On the Roof

Part 5 - Putting it All Together

The Rebate Application

The rebates being offered from Pasadena Water & Power (PWP) for this non-profit project were scheduled to step-down on December 1, 2011. Indeed, this was a substantial rebate reduction - 26% - such that failure to secure the existing rebate rates would have amounted to a hit of tens of thousands of dollars for our client. And PWP had made it very clear - unless applications were 100% complete and correct, they would be rejected and when resubmitted would be subject to the reduced rebate rates. Clearly the pressure was on to get this right the first time!

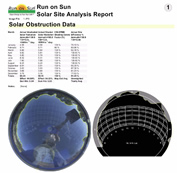

The application package consisted of eight parts - most of which were straight-forward, but a couple required substantial work to guarantee that the application as submitted would be acceptable the first time. Here are the parts that went into the rebate application: 1) Signed Rebate Application (PWP’s form, signed by client and Run on Sun under penalty of perjury!); 2) Single Line Diagram for the electrical components of the system (more on this below); 3) Site Plan; 4) CSI Report (as produced by the California Solar Initiative’s rebate calculator); 5) Shading Analysis (i.e., a Solar Pathfinder report to support the shading values used to create the CSI Report); 6) PWP’s Net Metering Agreement (executed by the client); PWP’s Net Metering Surplus Compensation form (for AB 920 compliance); and 8) Installation Contract between the client and Run on Sun. Also, since this was a non-profit client, proof of non-profit status was also required.

Shading Analysis & CSI Report

PWP wisely requires the submission of a shading analysis in addition to the output from the CSI rebate calculator. Since the amount of shading at the site directly impacts the performance of the system - and hence the CSI AC Watts of the system (or the predicted annual energy output in the case of a PBI rebate) - it really doesn’t make sense for a utility to simply trust that the installer is telling the truth about shading.

PWP wisely requires the submission of a shading analysis in addition to the output from the CSI rebate calculator. Since the amount of shading at the site directly impacts the performance of the system - and hence the CSI AC Watts of the system (or the predicted annual energy output in the case of a PBI rebate) - it really doesn’t make sense for a utility to simply trust that the installer is telling the truth about shading.

The output from the Solar Pathfinder proves that the shading numbers claimed are the shading values present at the site.

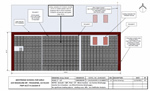

Site Plan

The site plan needed for the rebate application is a much simpler plan than what will ultimately be required for the permit, really only requiring an indication of where the various components of the system will be relative to the overall site. However, our system occupies three different areas of the PAC: the roof where the array itself is located, a ground-level storage area where our step-up transformer will be, and the utility switchgear, located on the far north end of the building. Thus our site plan included drawings for each location.

The array drawing showed the three sub-arrays and the clear space allocated for fire department access. Each sub-array consisted of three branch circuits, each of which was “center-tapped” to reduce the voltage drop in the associated branch circuits. Each branch circuit landed at a sub-array service panel which then fed a master “solar-only” sub-panel in the transformer area.

The array drawing showed the three sub-arrays and the clear space allocated for fire department access. Each sub-array consisted of three branch circuits, each of which was “center-tapped” to reduce the voltage drop in the associated branch circuits. Each branch circuit landed at a sub-array service panel which then fed a master “solar-only” sub-panel in the transformer area.

The transformer area drawing detailed the conduits coming down off the roof (one each from each sub-array sub-panel), the master sub-panel which feeds our step-up transformer (to change the 208 VAC three-phase power coming from the roof to 480 VAC three-phase supplied by the utility service) and then a safety disconnect switch located adjacent to the transformer. From the safety switch a fourth conduit carries the required conductors back across the roof to our service switchgear area.

The transformer area drawing detailed the conduits coming down off the roof (one each from each sub-array sub-panel), the master sub-panel which feeds our step-up transformer (to change the 208 VAC three-phase power coming from the roof to 480 VAC three-phase supplied by the utility service) and then a safety disconnect switch located adjacent to the transformer. From the safety switch a fourth conduit carries the required conductors back across the roof to our service switchgear area.

The service panel area drawing showed the placement of our lockable PV AC Disconnect, the associated performance meter, and our circuit breaker for the system located in the existing service switchgear.

The service panel area drawing showed the placement of our lockable PV AC Disconnect, the associated performance meter, and our circuit breaker for the system located in the existing service switchgear.

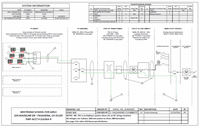

Single Line Diagram

Our most significant deliverable in the rebate application packet was the single line diagram (SLD) for the electrical circuits. Since this diagram shows how all of the electrical components of the power generating system interconnect - including the tie into the utility’s grid - we knew that this would be the most closely scrutinized piece of the submission. To be sure, PWP has a generic SLD that installers can use (in fact, we helped develop it!) but that drawing does not cover the use of Enphase Micro-inverters which we were featuring on this job, nor does it allow for a step-up transformer.

Fortunately, we had developed a very flexible SLD format from prior jobs that we could readily adapt for this project. However, before we submitted it to PWP, we forwarded it to the application engineers at Enphase Energy to make sure that they were comfortable with what we had designed. Enphase was more than accomodating - given our tight time frame they bumped us to the front of their engineering review queue and came back promplty with the good news - the design was good as we had drawn it and no revisions were needed. Of course, that was no guarantee that the utility would agree, but it is always nice to have a P.E. on your side!

Fortunately, we had developed a very flexible SLD format from prior jobs that we could readily adapt for this project. However, before we submitted it to PWP, we forwarded it to the application engineers at Enphase Energy to make sure that they were comfortable with what we had designed. Enphase was more than accomodating - given our tight time frame they bumped us to the front of their engineering review queue and came back promplty with the good news - the design was good as we had drawn it and no revisions were needed. Of course, that was no guarantee that the utility would agree, but it is always nice to have a P.E. on your side!

Included in the SLD preparation was a complete set of voltage drop calculations. This was complicated by the fact that we had 9 different branch circuits, three different sub-panels and two different operating voltages! Good design calls for limiting total voltage drop to less than 3%. To keep our worst case scenario within that limitation (covering the branch circuit farthest from the main “solar-only” sub-panel) we ended up with 4 different gauge sizes of conductors at different legs of the run: #12 in the branch circuit cables (supplied by Enphase), #8 from branch circuit jbox to sub-array sub-panel, #2 from sub-panel to main “solar-only” sub-panel, #3/0 from that sub-panel to the transformer and then #2 from the transformer back to the service equipment area. (One change that occurred during the install process increased the length of some of these runs - and that necessitated some wire size changes to insure that we stayed comfortably below our 3% limit. Those will be discussed in future episodes.)

One Big Present

All of those documents, plus pages and pages of cut sheets describing all of the key products being used, were then submitted to PWP - one day before the deadline! With no margin for error, our submission had to be perfect. Thankfully, it was - PWP gave us their official blessing to proceed three weeks later, just three days before Christmas. One big present, indeed.

Our first hurdle successfully surmounted, it was time to prepare for the most nerve wracking part of the process - pulling the permits! That’s the subject of our next installment - stay tuned!

12/06/11

Categories: All About Solar Power, PWP Rebates, PWP, Non-profit solar, Westridge PAC Project

Westridge Chooses Run on Sun for 54kW Solar Project

We are very pleased to report that one of the premier schools in Pasadena - or pretty much anywhere for that matter - the Westridge School for Girls has just selected Run on Sun to design and install a 54 kW solar power system on the Fran Norris Scoble Performing Arts Center.

It is very gratifying to have been chosen over some tough competition for this project, particularly given the School’s well-established commitment to sustainability. Indeed, just last year Westridge dedicated a new science building which has received the coveted, but very rare, LEED Platinum designation. Now as part of Westridge’s plan to “green” all of the campus, the 54 kW solar power system will be another dramatic step in that direction.

Even better, since the project will use Enphase micro-inverters, the students from grades 4-12 will be able to study the performance of the system right down to the individual panel level. We look forward to working with the Westridge faculty and administration as they teach their students about the difference that solar power can make in their lives.

At Run on Sun we have a special place in our hearts for working with non-profits and we would love to help your non-profit add solar too!

09/06/11

Categories: Solar Economics, Solar Tax Incentives, SEIA, SCE, Residential Solar, 2011

The State of Solar California - Outliers and Oddities - UPDATED x2!

UPDATE x2 11/8 - Solar City’s Jonathan Bass adds his perspective on our reporting about Solar City - see his response in the comments.

UPDATE 9/30 - We just heard from Jonathan Bass at SolarCity. Details at the end.

(Still no word from Galkos!)

Editor’s Note: We have now done an updated analysis showing the same data from 2012. You can read our 2012 Outliers & Oddities here.

In the first two installments in this series (Part 1 and Part 2) we looked at the most recent data from the California Solar Initiative (CSI) covering the first half of 2011 in SCE’s service area. Using that data we identified trends in cost, equipment and system efficiency. Along the way, we stumbled upon some Outliers and Oddities in the data that left us puzzled and disturbed. In this post we name names, specifically Galkos Construction (aka GCI Energy) and SolarCity.

Before we explain to you why they are featured in this post, we would remind our readers of the Solar Bill of Rights created by the Solar Energy Industry Association (SEIA) in the Fall of 2009. We wrote at some length about the Bill of Rights when it was introduced, but we want to highlight now what then we termed to be, “the most important right of all:”

8. Americans have the right, and should expect, the highest ethical treatment from the solar industry.

Beyond a shadow of a doubt, this is the most important Solar Right of all if we are to build an industry that is respected and trusted by consumers throughout this country. This should almost go without saying - and yet, saying it, and living it, is extremely important.

In our view, if we become aware of situations that don’t live up to that Right, we have an obligation to point them out so that our potential clients can make the most informed decisions possible.

In honor of that principle we present today’s post.

Outliers: Galkos Construction

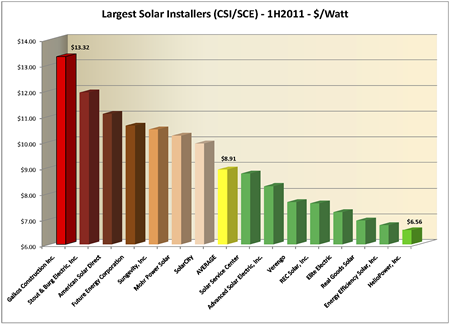

In looking at the data, from time-to-time a data point would jump right off the screen. For example, examining all of the residential projects in our data - both “completed” and “pending” but excluding “delisted” - we find that the average installation cost in CSI Rating AC Watts is $8.43/Watt (in DC or nameplate Watts that average becomes $6.99). As we noted in Part 1, that number has decreased over time and also decreases as system size increases. Still, given that the residential sector (as designated in the CSI data) only consists of systems between 1 and 10 kW, you wouldn’t really expect significant price variation between installers over a six month period.

But you would be wrong.

Who Charges What?

Here is a chart of the Cost per Watt for the largest installation companies in the SCE service area (you can click on the chart to see it full size):

First, let us give credit where it is due. The low end outlier is HelioPower, Inc., at $6.56/Watt, and they did it with an efficiency factor of 87% - second best of anyone on that chart. Nice.

But who is that way off in left field? Coming in at a staggering $13.32/Watt - a full $1.40 higher than their nearest competitor and more than twice what HelioPower is charging - is Galkos Construction, Inc., also known as GCI Energy, out of Huntington Beach. For that money, they must surely be offering only the most efficient and sophisticated technology, right? Not so much. To the contrary, the average installation efficiency for Galkos is only 84.9% - the second worst on the chart and well below the average of 86.11%. In fact, 99% of the time Galkos appears to use Sharp panels - not exactly an exotic solar panel brand - and in particular the Sharp ND-224UC1 panel (66.5%). A quick Google search reveals that the Sharp ND-224UC1 can be purchased, at retail, for $2.65/Watt or less. Given that Galkos handled 400 projects in this data set, it is hard to believe that their price for all of their equipment, particularly the Sharp panels, would not be heavily discounted.

Quality Counts

Quality, of course, is important, and the data does not reveal - though the Internet hints at - the quality of installations from Galkos. Here is how the company describes its own product offerings (from the “Services” page of their website):

Solar by GCI [Galkos Construction, Inc.] Energy

GCI Energy is the largest solar company in Southern California with over 30,000 customers. So you get the most knowledgeable professionals, excellent customer service and a better price.GCI Energy solar offers the highest efficiency solar panels on the market - those manufactured by Sharp. With Sharp Solar Panels, GCI Energy can tailor a solar panel installation to your specific needs and lifestyle, so you get maximum performance without a maximum investment.

(Emphasis added.)

Does Galkos actually have 30,000 solar customers? Certainly not (nobody does). Are they providing “a better price"? It is not clear what their standard of comparison might be - but their price is not better than any of their major competitors in that chart. And of course, the statement does not define what they mean by “the highest efficiency solar panels on the market,” but it seems unlikely that Sharp would make that claim. Here’s one chart that concludes that they couldn’t (note the efficiency of the SunPower and Sanyo panels first, then search for Sharp).

All we can say in response is, caveat emptor.

Oddities - SolarCity

Now we turn to the Oddities section of this post. Unlike the outliers, which were always of interest to us, we were not looking for the oddity we report here - it literally just jumped out at us.

Sold versus Leased

Question: What is the difference in reported cost between systems sold directly to the end customer and those that are leased (i.e., have a third-party owner in CSI parlance)?

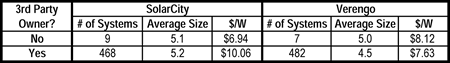

The initial difference that we stumbled upon was so startling that we knew we needed to narrow our focus and control for as many variables as possible to isolate that one factor. To achieve that end we restricted the data to those residential systems (i.e., between 1 and 10 kW) that were “pending” in the CSI/SCE data (thus, the newest proposed systems in the data which, based on our Part 1 analysis should mean the lowest cost systems). That way our project sample would be as homogenous as possible, eliminating cost variations based on system size and timing.

Given those restrictions, the top 5 installation companies in which the system is owned by a third party are: Verengo (482 systems), SolarCity (468), American Solar Direct (124), Sungevity (99), and HelioPower (63). Of those five, only two also have direct sales projects pending: Verengo (7) and SolarCity (9). Let’s see how they compare:

What is going on here? For Verengo, as the number of systems increases - which it does in going from sold systems to leased systems - their cost per Watt decreases - which is what we would expect. But not so for SolarCity - even though they are leasing 50 times as many systems as they are selling, their cost for the leased systems went up - way up - as in up by $3.12/Watt!

(One possible explanation for this discrepancy would be that SolarCity uses much more expensive equipment in their leased systems than they do in the ones that are sold. But they don’t. On their sold systems, SolarCity always selected a Fronius inverter and their panel choices were split among Yingli (56%), Kyocera (33%) and Sharp (11%). On their leased systems, SolarCity selected Fronius inverters 98% of the time and again split their panel choices among Yingli (68%), Kyocera (28%), and BP (3%) with the remaining 1% scattered among Suntech, Sharp and Sanyo. In other words, there is no significant difference in SolarCity’s equipment choices between sold and leased systems.)

Why Does this Matter?

Why does this significant cost differential matter, you might ask? After all, customers aren’t paying that price - they are paying on a lease so the “cost” of the system doesn’t matter to them, all they care about are their lease payments. True enough - unlike the case with our Outlier above, the end customer is not the victim here.

Recall, however, that for systems that are leased, the third-party owner - presumably SolarCity and its investors in this case - receives both the rebates and the tax benefits associated with the installation. While the rebates are independent of the system cost (they are paid based on CSI Watts), not so for the tax benefits. Commercial operators (even though these are residential installations they are treated as commercial projects for tax purposes) are entitled to both a 30% tax credit as well as accelerated depreciation based on the cost of the system.

For the 468 systems that SolarCity is leasing, their total cost is $24,261,735 to install 2,412 kW. If those installations were billed out at the $6.94/Watt they are charging for their sold systems, the installed cost would be $16,739,280 - a difference of $7,524,037. At 30% for the federal tax credit, taxpayers are giving SolarCity an extra $2,257,211 - just from six months worth of installs in only the SCE service area.

Wow!

In the words of the 70’s pop song, How long has this been going on?

How Long Indeed

We decided to find out.

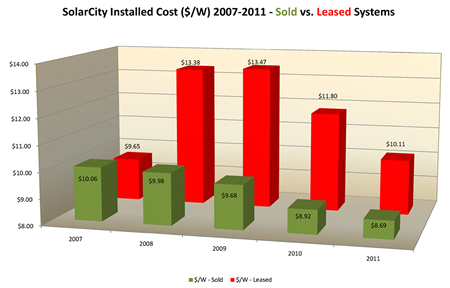

Although all of our analyses up until now in this series have been restricted to the first half of 2011, the actual data set contains entries from the inception of the CSI program. Thus we can look at all of SolarCity’s installs going back to 2007 and compare them as we did for the 1H2011 pending installs above. We will use the First Completed date to group these by year and analyze only “installed” - and not “pending” applications. Here’s the data:

The answer would appear to be, almost from the beginning! Back in 2007, Solar city sold ten times as many systems as it leased. By 2008 the ratio was down to 4-1 and ever since then leasing has been SolarCity’s predominant business strategy with the ratio of leased to sold now standing at nearly 16-1 in 2011.

Bottom Line

What, then, is the cumulative impact to SolarCity’s bottom line from this trend throughout California? We aren’t in a position to calculate the depreciation benefits (since that is a function of the system owner’s tax bracket) but we can readily calculate the added value derived from the 30% federal tax credit due to this increased cost per Watt.

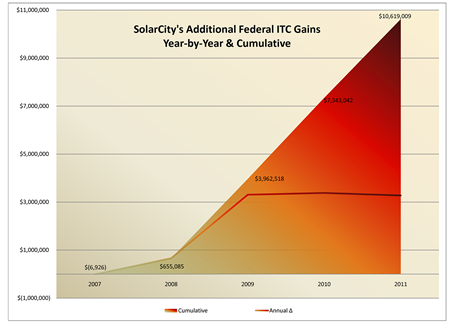

Here is our plot of the cumulative effect of those year-by-year increases:

After a slow start in 2007-08, SolarCity’s “model” really took off and has garnered the company an extra $3,000,000+ each year since 2009 (and, of course, 2011 is not yet over) for a total excess accumulation of $10,619,000. Depending on the investors’ tax bracket, the depreciation could be worth nearly as much as the tax credit.

Double Wow!

UPDATE 9/30 - We have now heard from SolarCity

We just heard from Jonathan Bass, Director of Communications at SolarCity who took exception with our report, although he did concede that he could see how we could have reached the conclusions we published in light of the CSI data. We encouraged him to please send us a written response in as much detail as he chose and we would publish it in its entirety. While he agreed that SolarCity would be publishing its response, he did not commit to publishing the information here.

In any event, when we hear more we will update this post again.

What’s Next?

No doubt there is more that we could do with these revelations - but wouldn’t it be better for those with actual oversight obligations to examine this data as closely as we have and to take appropriate action?

As always, we welcome your comments - and if we hear from any of the folks named in this series we will be sure to update the appropriate post.