Tag: "microinverters"

11/07/18

Categories: All About Solar Power, Residential Solar, Solar Repairs

Enphase announces Upgrade Program for Early Adopters...

One of the nagging concerns in the solar industry is what to do about those aging legacy systems? As systems age there can be reliability issues and finding compatible parts can be a real issue in a fast moving technology environment like solar power. Given all of that, we are pleased to announce the Enphase Update Program for Enphase Early Adopters. There is a lot to this program, including three distinct upgrade paths, so let’s break it down step-by-step…

Who is Eligible?

This program is dedicated to the earliest adopters of Enphase microinverters, specifically the M175, D380, M190, and M210 models. (Of the eligible microinverter models, Run on Sun only ever installed the M210.) System owners that have M215’s, M250’s, or S280 microinverters are not eligible for this program.

|

|

| The Enphase M210 qualifies for the upgrade… | While the subsequent generation M215 does not. |

What are My Options?

There are three upgrade paths with varying benefits, costs, and timing, however, all three offer full 25-year product warranties and a two year service agreement. The three options are: Microinverter Upgrade, Full-System Upgrade, and Next-Generation Upgrade - let’s take them one at a time.

Microinverter Upgrade

The most cost-effective option is the Microinverter Upgrade because it takes advantage of your existing solar panels that are likely still in good shape. This upgrade provides all of the following:

- New Enphase IQ7-PD - the latest generation microinverter, powered down to be compatible with existing, earlier generation systems.

- New interconnection cable

- New IQ Envoy with both production and consumption energy measuring devices* (CTs).

Legacy owners can purchase this equipment directly from Enphase for just $67.50/panel - a really great price. Removal and re-installation labor will vary widely based on various factors including the difficulty of the roof, the quality of the original installation, and whatever upgrades need to be done, probably on the order of $150/panel.

*Note that not all systems will be able to do consumption monitoring depending on the existing service panel configuration.

Full-System Upgrade

When microinverters like the M210 were being installed, available panel wattage was much lower than today, but with the advent of electric vehicles, homeowners are in need of more energy than ever. The Full-System Upgrade provides a way to gain from today’s higher power modules, but in a cost-effective manner.

Enphase Energized Solaria PowerXT-AC Modules

This upgrade path involves the Enphase Energized Solaria PowerXT-AC Module, which has an Enphase IQ7+ microinverter integrated onto the Solaria module. (You can see an image of the Solaria modules on the left.)

The module has a power production of 295 Watts, substantially greater than what was available for legacy modules. The cost to the homeowner for this upgrade path is $469/panel, which includes the AC module, cabling, and the Envoy for monitoring.

Labor costs for this upgrade path are likely to be substantially higher, in part due to the need for new racking (the module dimensions are somewhat unusual - 63.8″ x 43.9″ - which could necessitate a racking change), changes in the sizing of the branch circuits, and the need to pull permits for the new system. Those factors are mitigated somewhat by the upgrade cost most likely qualifying for the federal 30% tax credit since it is an all new system, as opposed to the Microinverter Upgrade, that won’t.

Next-Generation Upgrade

Finally, the last upgrade option is to wait for the rollout of the Enphase IQ8 microinverter system. (You can read about what the IQ8 technology will provide here.) Unfortunately, there is no pricing information available yet for that upgrade path, and its availability is not until sometime in 2019 - probably the second quarter at the earliest.

What Happens if I do Nothing?

If your system is working fine, you don’t really have a need to do anything. However, these earlier microinverters came with a 15-year warranty, which means that more than half of that warranty period has expired. Moreover, particularly compared to the M190’s, the newest Enphase microinverters have significantly greater reliability (Enphase claims by an order of magnitude), so you would be upgrading to a more reliable product and extending your warranty protection by 25 years.

We will post again when we have more information regarding the Next-Generation, IQ8 upgrade. In the meantime, if you have questions about upgrading, please give us a call.

08/17/18

Categories: All About Solar Power, Residential Solar, Energy Storage

What I Saw at Enphase - Mind Blown!

Last month during Intersolar, I (along with colleagues Sara and Victoria) was lucky enough to get invited to see a microgrid demonstration featuring the Enphase next-gen IQ8 at their headquarters in Petaluma, California. As I had to sign an NDA as the price of admission, I was unable to write about what I had seen until today, when Enphase hosted their annual Analyst’s Day. But I am no longer bound by that agreement, and can now tell you about what I saw.

Last month during Intersolar, I (along with colleagues Sara and Victoria) was lucky enough to get invited to see a microgrid demonstration featuring the Enphase next-gen IQ8 at their headquarters in Petaluma, California. As I had to sign an NDA as the price of admission, I was unable to write about what I had seen until today, when Enphase hosted their annual Analyst’s Day. But I am no longer bound by that agreement, and can now tell you about what I saw.

To say that I was impressed would be a gross understatement - quite simply, it was the most astonishing thing I have ever seen in the solar industry. Settle in and let me tell you what I saw…

What Happens Today

Before I launch into describing the demo, let me remind you of what happens today. All of the systems that we have installed are what is referred to as “grid-tied” which means that if the grid goes down, the PV system that is capable of back-feeding the grid also goes down, and remains down until the grid comes back. (This is to prevent your house from being an island of energy, feeding the grid, and potentially injuring a worker trying to restore grid service. As a result, this feature is known as “anti-islanding” and it is required of all inverter systems that are connected to the grid.)

Normally this is not a problem, but last month, when it got super hot out here (think 115° F hot!), both SCE and LADWP suffered dozens of outages, taking down PV systems across large swathes of LA County, and leaving frustrated PV owners without power, or A/C, just like their PV-less brethren. Not good.

What I Saw in the Lab

Which brings us to what I saw at Enphase last month.

The lab looked like an ordinary industrial space, but with a series of household appliances and tools at one side. There was a simulated array feeding a bank of IQ8 inverters, and a display that showed the output of the array (i.e., PV production), the total consumption from the loads, and any power being exported or imported to support those loads. At the start of the demo the only load was a single red lamp, and the display indicated that it was drawing roughly 90 Watts. The PV array was producing roughly 1.9 kWs, so the excess 1,800 Watts was being exported to the grid. All super normal stuff.

But then things got interesting…

One of the engineers switched off the breaker that connected the PV array to the grid… and nothing happened! Well, actually, a lot happened, but what didn’t happen was that the red light did not go off. It didn’t even flicker to the extent that we could detect it. But then when you looked at the display you noticed something amazing. Not only had the microinverters created a grid on their own in fractions of a second, but they had throttled the output down so that now the production of the PV array exactly matched the load of the red light! And here’s the kicker - there were no batteries attached to this system!!!

But what fun is just having a light on? How about some toast? So they switched on a toaster, and it lit up, and the total load jumped by about 1,000 Watts, making the total load now around 1.1 kW, and the PV array scaled up to meet it! Still no batteries. And how about this - there was no central controller, no master-slave relationship between the microinverters. Rather, this was the “hive mind” at work, as the micros sensed the demand and scaled up or down as necessary to meet that load!

But wait, there’s more!

The next load to be added was a grinder like you might find on your workbench in the garage. All by itself, that device drew roughly 1,200 Watts, bring our total load to roughly 2.3 kW - more than the maximum output of our simulated array. What would happen when that was added to the mix? Surprisingly little. The grinder spun normally, but the red light dimmed slightly. What was going on? The system’s “hive mind” had lowered the voltage slightly (a microgrid equivalent of a brown out) to meet the amperage demand of the new load mix! So slightly slower than normal, cooler than normal, dimmer than normal, but all operating.

Of course, all good things must come to an end. Our already overloaded microgrid faced one more challenge - a vacuum cleaner with a significant in-rush current, far in excess of what the grid could sustain. Indeed, as soon as they switched the vacuum cleaner to “on", everything shut off. Nothing was damaged, the microinverters just shut off to protect themselves.

Turning on the vacuum cleaner served as the “ah-ha” moment for the potential homeowner - I guess I can’t run everything in grid outage mode. So what do you do when something you just did produced an undesired result? Well if you can, you undo it! Turning the vacuum cleaner off, immediately restored the microgrid to its previous state of operation! No delay. No human intervention - just turn off that latest (over)load, and the system recovers on its own!

How cool is that? Pretty damn cool, if you ask me!

Batteries Please?

So what about batteries, how do they play with this new system? Just exactly as you would want.

The engineers added a bank of batteries to the mix, each with an IQ8 installed. Now the display also indicated the battery’s overall state of charge, and whether they were charging or discharging. Reset the demo to just the red light as a load and the batteries at 30% state of charge. The PV array output jumped back to its maximum, with the surplus energy being used to charge the batteries. As more loads were added, the PV array remained at maximum output, and as needed, drew power from the batteries. Should the batteries reach full capacity and the PV output is greater than the loads, the microinverters will once again throttle down.

Sweet!

What’s Next?

I hope you agree that this was an amazing demo, and the IQ8 (or Ensemble, as Enphase refers to the overall system) has tremendous potential, both for Enphase as a company, and for so many nascent markets. Think of how this product could have helped out in Puerto Rico, or in parts of Africa which have never, ever seen a grid! Makes me want to book a trip to bring power to a village somewhere - hey Laurel, what do you say?

For our own clients, this has the potential to be the answer we have been seeking ever since Elon’s whoppers got people thinking about storage for the first time ever.

A point we raised with Enphase management is the need to have a reasonable upgrade path for existing clients. Indeed, I have a call with Enphase tomorrow to discuss that very topic. We know that current Enphase IQ products (the 6+ and 7+ we have been installing this year) will be compatible with Ensemble. We expect to be able to work with older systems, though there may be a higher retrofit cost. When we have that information, we will surely let you know! The IQ8 is expected to be available in 1H2019… watch this space!

07/02/13

Categories: PWP Rebates, Commercial Solar, Non-profit solar, Westridge PAC Project

Westridge Case Study: Part 2 - Run on Sun Gets it Done!

In Part One of this three-part Case Study we learned how Westridge School chose Run on Sun as their solar contractor. Here in Part Two we focus on the actual process of the installation as seen from the client’s perspective.

Run on Sun Gets it Done

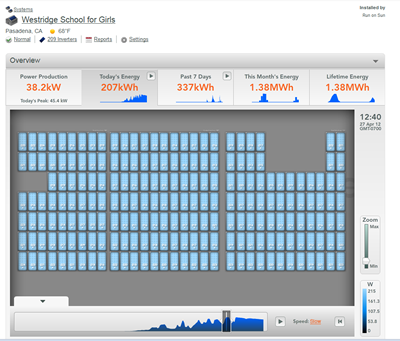

With the paperwork filed and the rebate secured, Run on Sun had a very tight window — less than two weeks in April 2012 — in which to install and connect all 209 solar modules and get the monitoring software up and running. The goal was for the project to be completed and operational by the time Westridge students returned from Spring break, so time was of the essence.

For the rooftop display Run on Sun used a microinverter system supplied by Enphase Energy, which allows customers and solar installers to track the output of the modules, individually or collectively, from the convenience of their computers, iPads or smartphones. This software was a selling point for the school, because it would make the technology accessible to students and allow teachers to creatively incorporate aspects of the solar system’s performance into classroom instruction.

For the rooftop display Run on Sun used a microinverter system supplied by Enphase Energy, which allows customers and solar installers to track the output of the modules, individually or collectively, from the convenience of their computers, iPads or smartphones. This software was a selling point for the school, because it would make the technology accessible to students and allow teachers to creatively incorporate aspects of the solar system’s performance into classroom instruction.

The modules were grouped into three sub-arrays that formed a larger circuit. Under each module, a microinverter was installed to convert DC energy gathered from the module into AC power, which could be combined and fed back into the school’s electrical service. The 1:1 ratio of microinverters to modules allows for a more detailed readout that lets users know the output of each module and gives an easy-to-read display should anything ever go amiss, from a connection issue to dirt on the module’s surface.

Throughout the installation Williams remained on hand to oversee the work, though there were no delays and no change orders requesting funds beyond what had been originally estimated. Within the assigned two-week period, Run on Sun had completed the project on time, and everything was in working order.

“I’ve worked with a lot of contractors, and I can honestly say, in this situation, this was one of the most seamless projects we’ve ever completed,” Williams recalls. “They were here early on the first day and, boom, they got it. It was done on schedule, at the price they said and signed off by the city. I wouldn’t hesitate to do a project like that again.”

A Truly Happy Anniversary

April 2013 marked the one-year anniversary of Westridge School’s solar installation, and Williams reports the system is running smoothly. The Enphase software makes it easy for officials, teachers and students to monitor the activity of all 209 modules, but Run on Sun also keeps a close eye on the operations and reaches out if and when an anomaly is detected. In the event that an outage or a decline in energy production should occur, the company promptly notifies the school.

For example, when one of the modules stopped reporting and apparently needed to be replaced, Run on Sun immediately contacted Williams to schedule a visit. The rest of the modules were still in full working order, and upon close inspection it was revealed that a connection had come loose. Still, to ensure maximum performance, the company replaced the microinverter at no cost to the school.

Another time Williams received a notification email from Run on Sun after the campus Internet connection had been temporarily cut during some service upgrades. And when the energy dipped from its norm of exceeding system predictions to 98 percent of anticipated, a call came in with a recommendation to check the array for accumulated dirt. After a brief spray with a hose, the system was back to producing at maximum capacity.

At the one-year mark, the school became eligible to receive its first annual rebate from Pasadena Water and Power. This is the first of five annual rebates it will receive, the dollar amounts directly correlated to the system’s actual production.

When a technician came from the city to assess the energy output of the system, the school was excited to learn the results. The city’s readings gave some very welcome news, indeed — the energy generated by the installation was above and beyond the original estimate provided to PWP, and it looked like the first rebate would be larger than anticipated.

“He said, ‘You’re over your estimate,’ and that’s all we could ask for,” says a thoroughly pleased Williams. “To date, everything that was promised to us was delivered — plus.”

In terms of the amount of energy generated, the rooftop system has continued to outpace expectations. The school expected to see a return on its investment in seven years, but it’s shaping up to come in as few as six. Because of the installation, Westridge is using 30 percent fewer kilowatt hours and is seeing its bills reduced by thousands of dollars each month, in addition to the rebate. The overall savings is far greater than the cost of running the air-conditioner in the gym, the initial impetus for bringing solar to campus. To Williams, making the decision to go solar was a “no-brainer.”

“The neat thing about this is it runs itself. If somebody walks onto campus, they don’t know we have a 52 kilowatt solar system on campus,” he adds. “They don’t see it. It doesn’t impact anything. All you do is save money.”

We will conclude this three-part Case Study with Part Three - Advice for the Solar Reluctant.

The preceding is an excerpt from Jim Jenal’s upcoming book, Commercial Solar: Step-by-Step, due out this summer.